Q46H/65 Chlorine Dioxide

Chlorine Dioxide is a powerful oxidizing agent used for disinfection of potable water, cooling towers, and food wash water. It is also widely used for the bleaching of pulp in paper mills. As a disinfectant, ClO2 has advantages over chlorine in that it does not react with ammonia and many organic compounds while proving more effective at controlling bacteria, spores, viruses, and cysts. It is particularly well suited for removing biofilms from the inside of piping systems.

ATI’s Model Q46H/65 Chlorine Dioxide Monitor provides an economical and reliable measurement system for water quality monitoring and controlling ClO2 treatment systems. With a variety of outputs including 4-20 mA analog, PID control and digital communications, the Q46H/65 is adaptable to any ClO2 application.

INTERFERENCE-FREE

CIO2 MEASUREMENT

Q46H/65 monitors use a polarographic membraned sensor to accurately measure ClO2 in water. The sensor operates much like a battery, generating current that is linearly proportional to the concentration of chlorine dioxide in solution. A ClO2 permeable membrane isolates the sensor from the measured sample and insures that the measurement is interference free.

Q46H/65 monitors use a polarographic membraned sensor to accurately measure ClO2 in water. The sensor operates much like a battery, generating current that is linearly proportional to the concentration of chlorine dioxide in solution. A ClO2 permeable membrane isolates the sensor from the measured sample and insures that the measurement is interference free.

Two versions of the sensor are available, a sensor intended for installation in a flowcell and a sensor intended for submersion applications. Requiring minimal maintenance, sensors are easy to use and easy to maintain. An integral RTD provides temperature compensation and allows temperature to be displayed and transmitted from the monitor.

SENSOR STABILIZATION

Chlorine Dioxide sensors require 2 to 4 hours of stabilization time when first installed or after membrane change. ATI offers a battery powered “polarizer” that can be used to stabilize a spare sensor so it is ready to run within a few minutes of installation. Polarizers simply plug into the sensor connector and require no adjustments.

Chlorine Dioxide sensors require 2 to 4 hours of stabilization time when first installed or after membrane change. ATI offers a battery powered “polarizer” that can be used to stabilize a spare sensor so it is ready to run within a few minutes of installation. Polarizers simply plug into the sensor connector and require no adjustments.

ClO2 Monitoring with Direct Membrane Sensing!

SENSOR & FLOWCELL OPTIONS

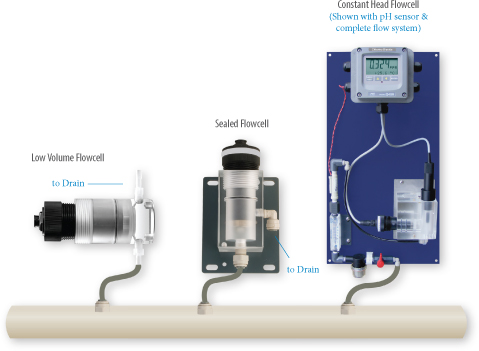

Chlorine Dioxide sensors require a steady flow of sample across the membrane at the tip of the sensing assembly. ATI offers a number of options for flowcells, including the standard constant-head overflow system, a sealed flowcell for pressures up to 50 PSI, and a low-volume flowcell where low sample flow is important. A 1-½” flow tee is also available for in-line applications with reliable constant flow and pressure conditions. For simplicity of installation, complete flow control assemblies are available.