Q46/76 Turbidity Monitor

General Details

Turbidity is a general indicator of the optical clarity of water and is defined as the amount of light scattered from particles in solution. In practice, a light beam is directed into a water sample and a photo detector measures the light scattered at 90-degrees to the incident light beam. While other scatter angles are possible, the 90-degree measurement angle has become the standard for turbidity measurement in most water systems. It is used as a relative indicator of the amount of suspended solids in solution, and is measured in virtually all drinking water systems. It is also used in industrial water treatment systems as an indicator of product water quality. ATI’s Model Q46T Turbidity Water Quality Monitor is designed to meet the needs of both municipal drinking water systems and industrial water treatment for reliable, low-range turbidity measurement.

Using an infrared or energy source in this 90 degree scatter measurement, the system provides high sensitivity measurement with unmatched zero stability. Turbidity measurements down to 0.001 NTU or as high as 2000 NTU can be measured with the same monitor, eliminating the need for separate high and low range instruments.

Turbidity Sensor

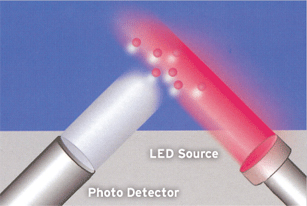

The turbidity sensor used in the Q46T monitor is a planer sensor with the light source and photo detector mounted on a flat face. Lenses in front of the light source direct the beam of light at a 45-degree angle into the sample. Another lens in front of the photo detector collects the 90-degree scattered light and directs it to the detector. The signal generated by the detector is amplified inside the sensor for transmission to the display unit. Periodic pulsing of the light source allows the sensor zero to be adjusted automatically for improved stability in low-range applications. Turbidity sensors are available for measurement in a pressurized flowcell or for direct submersion in open tanks. A 1-1/2” flow T assembly is also available for direct in-line measurements. The flowcell is required for very low measurements (0-2 NTU), while the submersion unit may be used for higher turbidity applications such as wastewater effluent or raw water.

Cross-section of turbidity sensor,

showing interaction of light beam and photo detector

Sensor Flowcell

Air bubbles are a common problem in many turbidity systems. ATI’s turbidity sensor is designed to operate under pressure to eliminate the sample degassing that often causes air bubble errors. Sample pressure remains constant until the sample exits the measuring chamber, resulting in a more reliable measurement. The turbidity electronics unit is an AC or DC powered instrument providing an LCD display of turbidity value, as well as indication of alarm status and instrument diagnostics. The NEMA 4X can be wall, pipe, or handrail mounted using the universal mounting kit included with each system.

Turbidity Monitor

The monitor provides display of turbidity over a variety of operating ranges. The minimum display range of 0-2 NTU provides resolution down to 0.001 NTU and is suitable for almost any final filter monitoring application. Ranges of 0- 20 or 0-200 NTU are available for raw water or clarifier effluent monitoring. The Q46T provides three programmable alarms with SPDT alarm relays are included, as well as two isolated 4-20 mA outputs. The analog outputs may be programmed for full-scale outputs as low as 0-0.2 NTU, and can be inverted if desired.

Q46T monitors also provide sensor diagnostic functions to warn of condition that cause inaccurate or invalid readings. The sensor is continuously monitored for optical fouling, and will display an alarm message when the sensor requires cleaning In addition, the sensor will detect the lack of water in the flowcell and provide a “dry cell” when an air interface is detected. These alarm conditions will cause a third alarm relay to activate, which can be used to indicate these conditions remotely.

Auto-Clean System for Wastewater!

ATI’s Q-Blast option provides the ideal answer for submersible turbidity applications such as wastewater effluent. Employing a unique “air-blast” cleaning method, sensors can be cleaned as often as necessary without operator attention. Pulses of pressurized air delivered through a nozzle at the tip of the sensor remove accumulated solids from critical sensing surfaces, resulting in accurate and reliable measurements.

The Q-Blast Auto-Clean assembly is housed in a NEMA 4X enclosure suitable for indoor or outdoor use. The system includes an integral compressor and air-pulse control components, with a power supply for the entire air supply system incorporated into the design. A simple connection to the Q46T monitor provides the sequencing for the system and allows the operator to select cleaning frequencies as often as once every hour to as little as once every 999 hours. To ensure performance in extreme cold conditions, a thermostatically controlled heater is included in the assembly, allowing operation down to -40°C.

Ominaisuudet

AC or DC Power Option

Power options include universal 100-240 VAC +/- 10%, or 12-24 VDC.

Extra Outputs

Expansion board to add a third 4-20 mA analog output or to add three additional non-isolated low power relays.

Flexibility

Wide range capability, with selectable ranges of 0-2.000, 0-20.00, 0-200.0 and 2000 NTU provide maximum application flexibility.

Wide range capability, with selectable ranges of 0-2.000, 0-20.00, 0-200.0 and 2000 NTU provide maximum application flexibility.

Analog Output Options

Two isolated 4-20 mA outputs are standard, with an option for a third output if required. Default setting provides analog outputs for turbidity and temperature.

Two isolated 4-20 mA outputs are standard, with an option for a third output if required. Default setting provides analog outputs for turbidity and temperature.

PID Output

Standard PID control function assignable to one analog output.

Standard PID control function assignable to one analog output.

Digital Communications

Communication options for Profibus-DP, Modbus-RTU, Modbus-TCP/IP or Ethernet-IP.

Communication options for Profibus-DP, Modbus-RTU, Modbus-TCP/IP or Ethernet-IP.

Relay Contacts

Three SPDT relays are standard, with relay functions programmable for alarm, control, or trouble indication. Three additional low power relays available as an option.

Three SPDT relays are standard, with relay functions programmable for alarm, control, or trouble indication. Three additional low power relays available as an option.

Flexible Mounting

NEMA 4X (IP-66) enclosure is suitable for wall, pipe, or panel mounting.

NEMA 4X (IP-66) enclosure is suitable for wall, pipe, or panel mounting.

Clear Display

Back-lit large LCD display provides clear visibility in any lighting condition. A scrolling second line on the display provides additional information and programming prompts.

Back-lit large LCD display provides clear visibility in any lighting condition. A scrolling second line on the display provides additional information and programming prompts.

Sensor Diagnostics

System automatically checks for sensor fouling, “dry cell”, and external light interference.

System automatically checks for sensor fouling, “dry cell”, and external light interference.