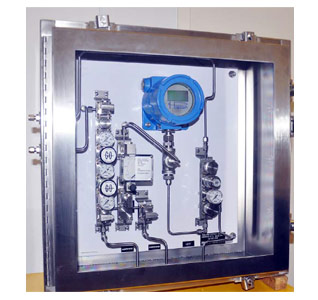

HY-OPTIMA™ 2700AS Process Hydrogen Analyzing System

H2scan’s HY-OPTIMA™ Model 2700AS Process Hydrogen Analyzing System provides a complete solution for process hydrogen measurement in refineries, chemical plants, air separation units and industrial gas manufacturing plants. The system implements H2scan’s hydrogen specific analyzer in a NEMA 4X enclosure with the necessary sample conditioning components to enable operation over a broad spectrum of process conditions.

Sensor Performance

Hydrogen Sensitivity Range:

0.5% to 100% hydrogen by volume at 1 ATM

Response Time: T90 < 30 sec

Ingress Protection: IP64 capable

Recommended Verification Interval: 90 days

Product Life Expectancy: 10 years

Accuracy(*):

± 0.3% absolute for 0.5 to 10% H2

± 1.0% absolute for 10 to 100% H2

Drift/week:

± 0.2% absolute for 0.5 to 10% H2

± 0.4% absolute for 10 to 100% H2

Repeatability:

± 0.2% absolute for 0.5 to 10% H2

± 0.4% absolute for 10 to 100% H2

Linearity:

± 0.2% absolute for 0.5-10% H2

± 0.4% absolute for 10-100% H2

Interface Options

Analog Output: 4 to 20mA

Serial Communication: RS232/422

Two built-in relays

Fault relay

Operating Conditions

Inlet Conditions:

Inlet pressure: 30 to 510 PSIG*

Process temperature: -20 to 100ºC*

Operating Voltage: 15VAC/230VAC

Enclosure Classification: NEMA 4X

Sample Flow Rate: .8 to 1 SLPM*

Accessories*

Vortex Cooler

Enclosure Heater: 200 Watts, 1.74 Amps at 115 VAC

Flow Meter

Pressure Transducer

Typical Dimensions*

Length: 24’’

Height: 24’’

Width: 10’’

Support & Warranty

1 year all parts and labor

Field support available upon request

Series 2700 Certification

UL Class1 Div1 Groups B,C,D

ATEX Ex Proof Ex d IIB + H2 T4 Gb