- Home

- Tuotteet

- Prosessimittaukset

- Ametek

- Ametek 5910 UHP Moisture Analyzer

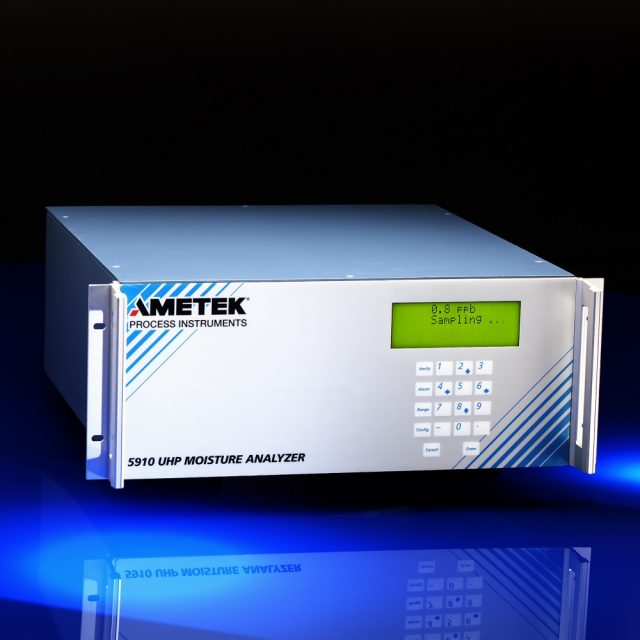

Ametek 5910 UHP Moisture Analyzer

- General Details

- Specification

- Documents

- Certificate

Model 5910 UHP Moisture Analyzer

The Model 5910 provides a quantum leap forward in performance across all measurable parameters. The 5910 is sensitive to changes in moisture concentration of less than 500 pptv. We know this because the nominal noise level is below 50 pptv. The result of these phenomenal abilities is an accuracy of better than ±100 pptv or ±10% of reading.

Typical Applications

Continuous Monitoring

Continuous moisture analysis is a valuable tool for quality assurance and process monitoring. As a quality assurance analyzer, the Model 5910 verifies that specified gas purity levels are maintained at on‑site separation, bulk delivery and distribution system transfer points, and ultimately, at points-of-use. The Model 5910 satisfies all the demands of continuous monitoring—principally low detection limit, high measurement accuracy, and internal verification.

Analytical Carts

The Model 5910 is the perfect analyzer for temporary monitoring applications for verifying installation, maintenance, or repair of gas distribution systems. Such temporary or spot testing makes excellent use of the unique combination of capabilities provided by the Model 5910—very fast response speed, especially to decreasing moisture concentrations for monitoring system dry-down; complete compatibility with O2, H and inerts; rapid start-up response; and the ability to quickly change from one gas to another.

See the AMETEK Products specific to the Photovoltaic Industry (Click Here)

Model 5910 UHP Specifications

| Compatible Gases: | Inerts (He, Ar, Ne, Xe, Kr) O2, H2, N2. Contact AMETEK to confirm compatibility with other gases. |

| Range: | Calibrated from 0 to 150 ppbv. Trend indication to 1000 ppbv. |

| Limit of Detection: | 150 pptv nominal |

| Accuracy: | ±100 pptv or ±10% of the reading, whichever is greater |

| RMS Noise: | 50 pptv |

| Response Time: | Typically 80% of a 25 ppbv step change in either direction in 10 minutes or less |

| Inlet Pressure: | 138 to 345 kPa (20 to 50 psig). Specified performance is obtained when the inlet gas pressure is maintained within ±17 kPa (±2.5 psi) |

| Exhaust Pressure: | Atmospheric |

| Sample Flow Requirement: | Less than 3 slpm |

| Inlet Gas Temperature: | 0º to 100ºC (32º to 212ºF). Optimal results are obtained when the inlet gas temperature is maintained at 60ºC (140ºF) |

| Outputs: | Four line by 20 character LCD display One self-powered 4 to 20 mA, into 100 to 500 ohm load analog output; can be configured for loop-powered operation RS484 and RS232 serial ports |

| Alarms: | System alarm, concentration alarm,a nd data valid 30 VAC or 60 VDC max, 50 VA or 1A max, resistive |

| Environmental Conditions: | Ambient temperature range 10º to 30ºC (50º to 86ºF) Optimal results are obtained when ambient is maintained within ±5ºC (±9ºF) Relative humidity 90%, noncondensing Pollution degree 2 Maximum altitude 2000 meters (6560 ft) Installation category II Indoor Use Only |

| Utility Requirements: | 100 to 132 VAC or 230 VAC ±10%, 47 to 63 Hz, 185W Instrument Air: 550 to 690 kPa (80 to 100 psi) -40ºC dew point |

| Mounting Configuration: | 19″ rack |

| Dimensions(WxHxD): | 48×17.7×50.9 cm (19x7x20 in) |

| Net Weight: | 15.9 kg (35 lb) |

Product Data Sheet

Application Notes

- UL/CSA General Safety Requirements

- UL/CSA Class I, Division 2, Groups A, B, C, D T4

- Complies with all Relevant European Directives